Machinery production

In 2014, Erlen purchased a machine shop on the site of the former STS Opava-Jaktař. This expanded our production capabilities to include engineering and construction production. Within the scope of engineering production, we are engaged in the production of engineering components for large technological units, as well as in the production of building and industrial steel structures, including surface treatment by hot-dip galvanizing under our own direction.

Machinery production possibilities

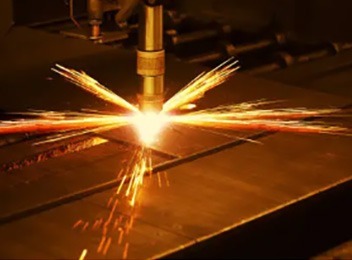

Plasma and gas burning

Plasma and gas burning in thicknesses of 1-100 mm

Press brake bending

Bending up to a maximum length of 4000 mm in thicknesses of 1-15 mm

Sheet metal cutting

Sheet metal cutting up to a length of

3150 mm in thicknesses 1-16 mm

Welding, drilling, machining

Welding of prepared blanks, drilling or machining is a matter of course for us.

Surface treatment

We provide hot-dip and thermal-diffusion galvanizing in our own galvanizing plants. Other types of surface treatments according to the customer’s requirements are carried out in cooperation.

Quality Certificates

Production Control Certificate of Conformity

for structural steel building parts, components, assemblies and structures according to EN 1090-2+A1:2011

IIW manufacturer certification system

for products: manufacture of engineering components for large technological units; manufacture of building and industrial steel structures; welding

References

Little mammoth‘s adventure park, Dolní Morava

galvanized steel construction

Sky walk, Dolní Morava

steel construction parts

Kaplice outlook tower

steel construction parts

Whale, Skalka family park, Ostrava

steel construction

Quarry machine

steel structures

Technosvar Ostrava

robotic cooling tower